Explain the terms ( Kinetic energy) Conduction, convection and radiation.

Indirect cooling?

Direct cooling?

What are the the problems you get with indirect and direct cooling?

What is the purpose of a thermostat?

Pressure cap?

Why is engines fitted with a core plug, and what is the purpose of a core plug

What is the purpose of a heat exchanger?

How does the heat exchanger work?

How does the centrifugal circulating water pump work?

Why is it important to lubricate the impellor when fitting from new?

When fitting a impellor what should you check before refitting the housing and why?

What is the process of a intercooler/after cooler how does it work?

Why do we have Inhibitors & antifreeze?

How do you test Antifreeze?

What is galvanic corrosion?

Describe the terms

Stray corrosion?

Stress corrosion?

Corrosion Fatigue?

Crevice corrosion?

What is Electrolysis?

How do you prevent corrosion?

What are sacrificial anode made off?

Conduction:

Heat spontaneously flows from a region of higher temperature to a region of lower temperature, temperature differences over time, approaching thermal equilibrium.

Info from: http://en.wikipedia.org/wiki/Conduction_%28heat%29

Radiation

Thermal radiation is electromagnetic radiation generated by the thermal motion of charged particles in matter. All matter with a temperature greater than absolute zero emits thermal radiation.

Examples of thermal radiation include visible light emitted by an incandescent light bulb, infrared radiation emitted by animals and detectable with an infrared camera, and the cosmic microwave background radiation.

Info from: http://en.wikipedia.org/wiki/Thermal_radiation

Convection:

Convective heat transfer, often referred to as convection, is the transfer of heat from one place to another by the movement of fluids. The presence of bulk motion of the fluid enhances the heat transfer between the solid surface and the fluid. Convection is usually the dominant form of heat transfer in liquids and gases.

Info from: http://en.wikipedia.org/wiki/Convective_heat_transfer

An image showing the different types of heat transfer:

And a song from YouTube about this stuff

Direct cooling:

The difference between direct cooling systems and indirect cooling systems, also known as secondary refrigeration, lays in the physical separation between the primary circuit, where the cold is generated, and the secondary system, where cooling takes place.

Info from: http://www.zitrec.com/Applications_indirect_cooling_systems.htm

Image from: http://www.betterbricks.com/building-operations/cooling-towers

Indirect cooling:

Indirect cooling in supermarkets

The combination of these benefits is why typically in public buildings, such as supermarkets, indirect systems are promoted. In supermarkets, the cold needs to be transported to a variety of fresh and frozen displays in an effective, safe and economical way. All the cooling effect required is produced in the machine room, far from the display cases, resulting in high flexibility and a lower risk of leakage. A heat recovery system, also situated in the machine room, can provide heating for the supermarket when required. In this way the use of unwanted refrigerant such as ammonia in a public place is avoided, although it can still be used in the primary system, kept in a safe sealed room, away from the public.

(info from: http://www.zitrec.com/Applications_indirect_cooling_systems.htm)

The purpose of a Thermostat:

The thermostat acts as a valve that stays closed during engine warm-up. When the thermostat is closed, it prevents coolant from leaving the engine and circulating through the radiator. When the engine gets warm, the thermostat’s spring valve opens, allowing coolant to circulate through the radiator to be cooled.

(Info from: http://www.matthewsvolvosite.com/replace-thermostat-volvo-850-s70-v70-c70-or-xc70.html)

(Image from: http://www.matthewsvolvosite.com/replace-thermostat-volvo-850-s70-v70-c70-or-xc70.html)

Pressure cap:

(image from: http://www.motorera.com/dictionary/pr.htm)

The radiator cap actually increases the boiling point of your coolant by about 45 F (25 C). How does this simple cap do this? The same way a pressure cooker increases the boiling temperature of water. The cap is actually a pressure release valve, and on cars it is usually set to 15 psi. The boiling point of water increases when the water is placed under pressure.

When the fluid in the cooling system heats up, it expands, causing the pressure to build up. The cap is the only place where this pressure can escape, so the setting of the spring on the cap determines the maximum pressure in the cooling system. When the pressure reaches 15 psi, the pressure pushes the valve open, allowing coolant to escape from the cooling system. This coolant flows through the overflow tube into the bottom of the overflow tank. This arrangement keeps air out of the system. When the radiator cools back down, a vacuum is created in the cooling system that pulls open another spring loaded valve, sucking water back in from the bottom of the overflow tank to replace the water that was expelled

(info from: http://auto.howstuffworks.com/cooling-system7.htm)

Core plugs and their purpose:

Core plugs, sometimes wrongly called freeze plugs or frost plugs, are plugs that fill the core holes found on water cooled internal combustion engines. The sand casting cores are used to form the internal cavities in the engine block or cylinder head(s), usually forming the coolant passages. The traditional plug is a thin, domed, disc of ferrous metal which is pressed into a machined hole in the casting. Alternatively a non-ferrous metal such as brass offers improved corrosion prevention.

(Info from: http://en.wikipedia.org/wiki/Core_plug)

(Image from: http://www.pauls-place.com/products-chevy-block-accessories.asp)

The purpose of a heat exchanger:

The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air.

(info from: http://en.wikipedia.org/wiki/Heat_exchanger)

(Image from: http://en.wikipedia.org/wiki/File:Straight-tube_heat_exchanger_1-pass.PNG)

How the heat exchanger works:

There are two primary classifications of heat exchangers according to their flow arrangement. In parallel-flow heat exchangers, the two fluids enter the exchanger at the same end, and travel in parallel to one another to the other side. In counter-flow heat exchangers the fluids enter the exchanger from opposite ends. The counter current design is most efficient, in that it can transfer the most heat from the heat (transfer) medium. In a cross-flow heat exchanger, the fluids travel roughly perpendicular to one another through the exchanger.

(Info from: http://en.wikipedia.org/wiki/Heat_exchanger#Flow_arrangement)

Parallel flow heat exchanger:

(image from: http://en.wikipedia.org/wiki/File:Heat_exc_1-1.svg)

Cross flow heat exchanger:

(image from: http://en.wikipedia.org/wiki/File:Heat_exc_2-1.png)

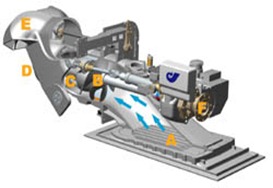

How does the centrifugal circulating water pump work?

The centrifugal pump is powered by an electric motor in a waterproof housing. That motor drives a device called an impeller. The impeller is a wheel with angled blades. When water gets caught in it, it is driven by centrifugal force to the outside of the spinning wheel. The shape of the blades then compresses the water and shoots it out in a jet

(info from: http://www.ehow.com/how-does_4963320_circulator-pump-work.html)

(Image from: http://media.web.britannica.com/eb-media/58/3658-004-061948E8.gif)

Why is it important to lubricate the impellor when fitting from new?When the impellor is fitted from new, it will be dry, and all impellors rely on being wet as a way of lubrication, so a little silicone is to be used so that the impellor can turn/slip easily in the housing before it is surrounded by water.

When fitting a impellor what should you check before refitting the housing and why?When refitting a new impellor, check to see if there isn’t any shredding or cracks, because when the impellor turns, the force of the water will have a possibility of stressing the weakened area and cause it to get bigger until a blade is torn off and jams the pump.

What is the process of a intercooler/after cooler how does it work?

An intercooler (sometimes referred to as an aftercooler) is designed to remove heat from the compressed air coming from the supecharger (or turbo) before it enters the engine's induction system. An intercooler works just lie a radiator - air is cooled by fins, bars, louvres, and plates inside the intercooler that are cooler than the compressed air coming from the supercharger. The reduction in air temperature increases the density of the air (more air molecules per cupic foot), which consequently increases your engine's ability to make more horsepower and torque. The decreased air temperature allows you to run more boost on a given octane of fuel before detonation occurs..

(Info from: http://www.angelfire.com/hiphop3/ppddaiddddyy/Intercoolers.html)

(image from: http://heatexchanger-design.com/wp-content/uploads/2011/02/intercooler.jpg)

Why do we have Inhibitors & antifreeze?

Antifreeze (engine coolant) performs several functions in addition to providing freeze protection. Antifreeze contains chemicals that inhibit corrosion and scale formation in the engine and radiator. Antifreeze (engine coolant) provides protection against boiling in the summer. At one atmosphere pressure pure water boils at 212 °F (100 °C) but a 50/50 blend of water/ethylene glycol boils at 223 °F (106 °C).

(info from: http://www.eetcorp.com/antifreeze/antifreeze-faq.htm#q2)

(image from: http://mypetshappiness.com/wp-content/uploads/2009/07/iStock_000001212761XSmall.jpg)

How do you test Antifreeze?

What is galvanic corrosion?

Galvanic corrosion is an electrochemical process in which one metal corrodes preferentially to another when both metals are in electrical contact and immersed in an electrolyte. The same galvanic reaction is exploited in primary batteries to generate a voltage.

(info from: http://en.wikipedia.org/wiki/Galvanic_corrosion)

Describe the terms

Stray corrosion: Stray current corrosion refers to corrosion damage resulting from current flow other than in the intended circuit(s).

Stress corrosion: Failure by cracking under the conjoint action of a constant tensile stress, which is applied to residual, in certain chemical environments specific to the metal.

Corrosion Fatigue: Damage to or failure of a metal due to corrosion combined with fluctuating fatigue stresses.

Crevice corrosion: Corrosive degradation of metal parts at the crevices left at rolled joints or from other forming procedures; common in stainless steel heat exchangers in contact with chloride-containing fluids or other dissolved corrosives. Also known as contact corrosion.

(Info from: http://calvinbayley.blogspot.com/search?updated-max=2011-06-27T13%3A16%3A00-07%3A00&max-results=7)

What is Electrolysis?In chemistry and manufacturing, electrolysis is a method of using a direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction.

(Info from: http://en.wikipedia.org/wiki/Electrolysis)

How do you prevent corrosion?10 ways to prevent corrosion:

(info from: http://www.smithandarrow.com.au/blog/rust-corrossion/10-ways-prevent-corrosion-metals/)

What are sacrificial anode made off?

Sacrificial anodes are made off zinc, and are very common in the marine industry, to help protect components in the salty environment.

(info from: http://calvinbayley.blogspot.com/search?updated-max=2011-06-27T13%3A16%3A00-07%3A00&max-results=7)